Why Windows & Skylights Fail

How To Detect & Test For Failure - And Restoration Solutions

Condensation is the accumulation of liquid water on relatively cold surfaces. This is why it is easier to detect seal failure during the colder months. It is also why the testing process works.

Almost all air contains water vapor, the gas phase of water composed of tiny water droplets. The molecules in warm air are far apart from one another and allow the containment of a relatively large quantity of water vapor. As air cools, its molecules get closer together and squeeze the tiny vapor droplets closer together, as well. A critical temperature, known as the dew point, exists where these water droplets will be forced so close together that they merge into visible liquid in a process called condensation.

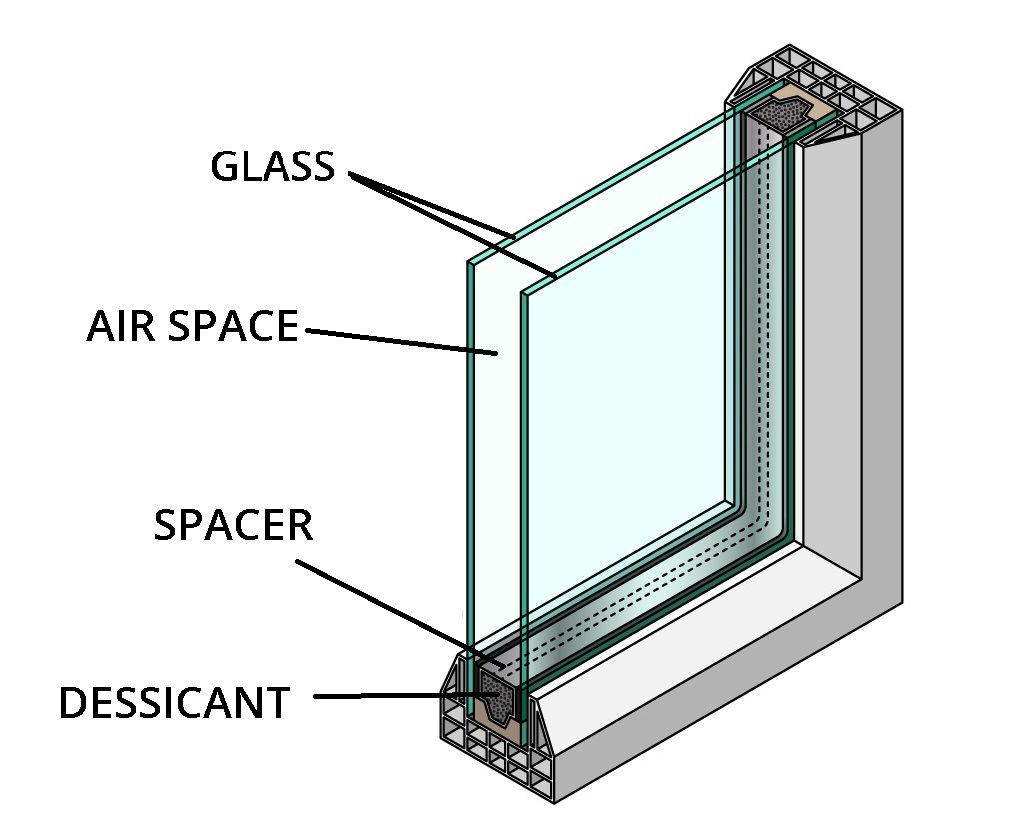

Double-pane windows & skylights have a layer of gas (usually argon or air) trapped between two panes of glass that acts as insulation to reduce heat loss through the window or skylight. Other types of gas used in this space have various effects on heat gain or loss through the window or skylight. If multiple-pane windows appear misty or foggy, it means that the seal protecting the window assembly has failed and the desiccants used are becoming oversaturated.

A desiccant is an absorbent material designed to maintain dryness in the space it protects. In a double-paned window, silica beads inside the aluminum spacer bar absorb moisture from any incoming air that enters the space between the panes. If not for the silica desiccant, any moisture in the space between the panes would condense on the glass as the glass cools below the dew point temperature.

Silica gel has an immense surface area, approximately 7,200 square feet per gram, which allows it to absorb large amounts of water vapor. As the sealant protecting this space fails over time, increasing amounts of moisture-containing air will enter the space between the panes, and the silica beads will eventually become oversaturated and will no longer be able to prevent condensation from forming. A double-paned window (Insulated Glass Unit or IGU) that appears foggy or that has visible condensation has failed and needs to be repaired or replaced.

Why Double-Paned Windows & Skylights Fail:

Solar (Thermal) Pumping

Although double-paned windows skylights appear to be stable, they actually experience a daily cycle of expansion and contraction caused by solar pumping. Sunlight heats the glass and airspace between the panes and causes the gas there to heat up and expand, pressurizing the space between the panes and slowly forcing some out. At night, the window or skylight cools and the space between the panes contracts and draws fresh (moist) air in. This motion acts like the bellows of a forge and is called solar pumping.

Over time, the constant pressure fluctuations caused by solar pumping will stress the seal. Eventually, the seal will develop small fractures that will slowly grow in size, allowing increasing amounts of infiltration and exfiltration of air from the space between the panes.

Failure Factors

Windows & skylights on the sunny side of a home will experience larger temperature swings, resulting in greater amounts of solar pumping, seal stress and failure rates.

Vinyl window frames have a higher coefficient of expansion resulting in greater long-term stress on the double-pane assembly, and a higher failure rate. Windows also experience batch failure, which describes production runs of windows, especially vinyl windows, that are defective, meaning that the pane assemblies have been manufactured with seals that have small defects that will cause the window to fail prematurely.

The Nature of Damage

If it’s allowed to continue, window & skylight condensation will inevitably lead to irreversible physical damage. This damage can appear in the following two ways:

- Riverbedding. Condensed vapor between the glass panes will form droplets that run down the length of the window or skylight. Water that descends in this fashion has the tendency to follow narrow paths and carve grooves into the glass surface. These grooves are formed in a process similar to canyon formation.

- Silica Haze. Once the silica gel has become oversaturated, it will be eroded by passing air currents and accumulate as white “snowflakes” on the window surface. Once this occurs the IGU needs to be replaced.

Detecting Failure

Condensation is not always visible. If the failure is recent, a failed window or skylight may not be obvious, since condensation doesn’t usually form until the window or skylight is heated by direct sunlight. Windows & skylights in the shade may show no evidence of failure.

The simplest and fastest way to test windows & skylights for failure is using a can of compressed air such as a can of “air duster”. When the can is turned upside down hold about 6” from glass surface to be tested and spray for about 4-6 seconds until you freeze the surface. Allow this spot to freeze the glass for about 15-20 seconds. Wipe away with a microfiber or terry cloth towel. If a spot of condensation appears inside the IGU then the unit has failed.

Recommendations for Failed Windows & Skylights

Depending on the type of glass and level of failure there are 3 options.

1. Drilling and venting (must be annealed glass caught in the beginning stage of seal failure).

This repair method proceeds in the following order:

- A hole is drilled into the windows or skylight, usually from the outside, and a cleaning solution is sprayed into the air chamber.

- The solution and any other moisture are sucked out through a vacuum.

- A drying agent (alcohol based) is sprayed in and also vacuumed out.

- Vents are permanently inserted into the holes that will allow the release of moisture during solar pumping.

- When a window is vented it does lose some insulating value.

2. IGU replacement (glazing). All tempered glass must be replaced once the seal has failed. Drilling into tempered glass causes it to shatter. Replacing the IGU is beneficial for several reasons.

- New seal and the highest insulating value.

- You can upgrade the glass to low-e and add or remove internal grids.

- Upgrade to a better/safer glass type (replace annealed with tempered or laminated).

- Less expensive than window or skylight replacement.

- Much less time required to replace an IGU than a complete window or skylight.

3. Complete window or skylight replacement. (very costly)

In summary, condensation in double-paned windows or skylights indicates that the glazing assembly has failed and needs repair or replacement. Visible condensation can damage glazing and is the main indication of sealant failure.

Save Up to 75% Versus Replacement!

© 2004-2024 Skylights Medics & Window Medics Plus | Privacy Policy

Web Design & Maintenance by: HiredHandDesign.com